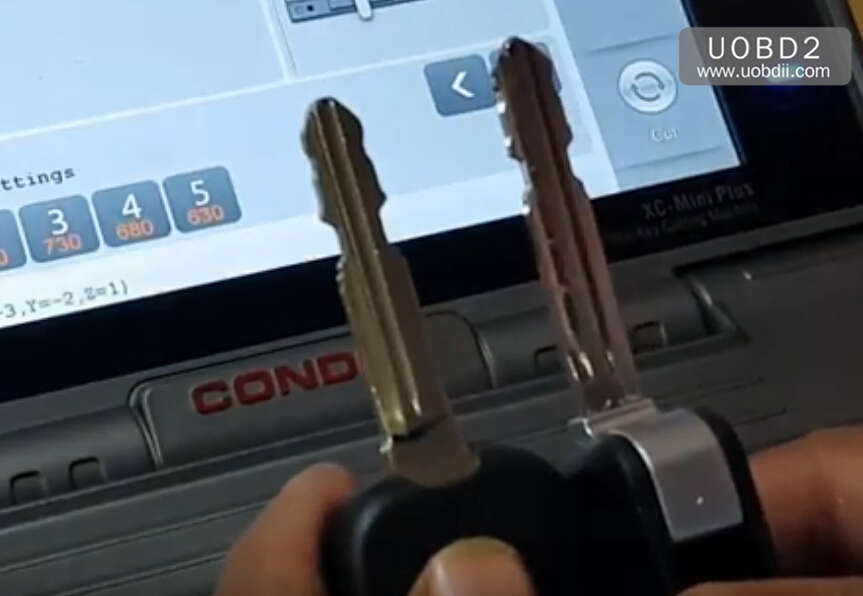

How to Use Xhorse XC-Mini Cut Key for GMC B102 Key

Here keycuttingmachine.org will show the procedures on how to use Xhorse XC-Mini to cut GMC B102 key.Now this key cutting machine is stop production,the replacement is Xhorse Condor XC-MINI Plus Steps: Select Car Maker “GMC”,then click Confirm Input key… Continue Reading